Introduction

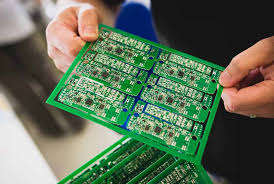

Through-Hole technology is a traditional method of mounting electronic components onto printed circuit boards (PCBs), offering distinct advantages and applications in electronic assembly. In this article, we’ll explore the intricacies of through-hole technology and its relevance in modern PCB manufacturing.

Understanding Through-Hole Technology

Definition

Through-Hole technology involves inserting component leads through holes drilled in the PCB and soldering them to pads on the opposite side of the board. This method provides mechanical stability and reliable electrical connections, making it suitable for various applications.

Components Used

Through-Hole technology accommodates a wide range of electronic components, including resistors, capacitors, diodes, transistors, and integrated circuits (ICs). These components feature leads or pins designed for insertion into PCB holes.

Through-Hole Assembly Process

Hole Drilling

The through-hole assembly process begins with drilling holes in the PCB substrate at specified locations corresponding to component placement on the board. These holes are typically plated with conductive material to facilitate soldering.

Component Insertion

Electronic components are manually or automatically inserted into the drilled holes on the PCB. Component leads protrude through the holes and are bent or trimmed to secure the components in place.

Soldering

Once components are inserted, the PCB undergoes soldering to create electrical connections between component leads and the PCB pads. Solder is applied to both sides of the board, forming solder joints that secure the components and provide electrical continuity.

Inspection

After soldering, the PCB undergoes inspection to ensure proper soldering and component alignment. Visual inspection, automated optical inspection (AOI), and X-ray inspection are commonly used to detect soldering defects and ensure quality.

Advantages of Through-Hole Technology

Mechanical Stability

Through-Hole technology provides robust mechanical connections between components and the PCB, making it suitable for applications subjected to mechanical stress or vibration.

Serviceability

Components mounted using Through-Hole technology are easily replaceable, facilitating maintenance and repair of electronic devices.

High Power Handling

Through-Hole components typically have higher power-handling capabilities than surface-mount components, making them suitable for high-power applications such as power electronics and industrial equipment.

Conclusion

Through-Hole technology remains a relevant and widely used method of mounting electronic components onto PCBs, offering mechanical stability, serviceability, and high power-handling capabilities. While surface-mount technology (SMT) has gained prominence in recent years, Through-Hole technology continues to play a vital role in various applications where robustness and serviceability are paramount. To learn more about Through-Hole technology and PCB manufacturing, visit through-hole.